• Made in USA •

GOD BLESS AMERICA

CPR's new line of Big Tube Headers provide the adequate exhaust needed by high performance engines to produce maximum horsepower and torque. Bringing the high performance and racing Mustang enthusiast a custom designed header at a fraction of the cost of custom built on your car header was our mission, we did it! Most of our headers are the long tube design with full racing style collectors and our exclusive "Rotational Firing Pattern" RFP design which creates a draw through exhaust system freeing up to 40 additional horsepower! Each header is individually hand-crafted in the USA around your particular engine block deck height, cylinder head type, bell housing and transmission combination. These are not a one size fits all cheap production headers. Built from heavy wall tubing and laser cut one piece flanges to assure long lasting dependable performance, they come second to none in quality & performance!

Have them coated for additional life span and cooler under hood temperatures!

The headers are designed to fit any '79 through '95 Mustang (or FOX chassis) using the stock OEM front K-member and engine mounting location. Two designs are also set up for the '65 through '73 Mustang. Remember, these are race headers and as such, due to tubing and collector size, ground clearance may be affected. Some can be configured to fit Ford Lightning Trucks.

Because each custom header is built to order, please allow three to four weeks from date of order until shipping.

For more information or technical assistance with header selection mail headers@cprparts.com today!

|

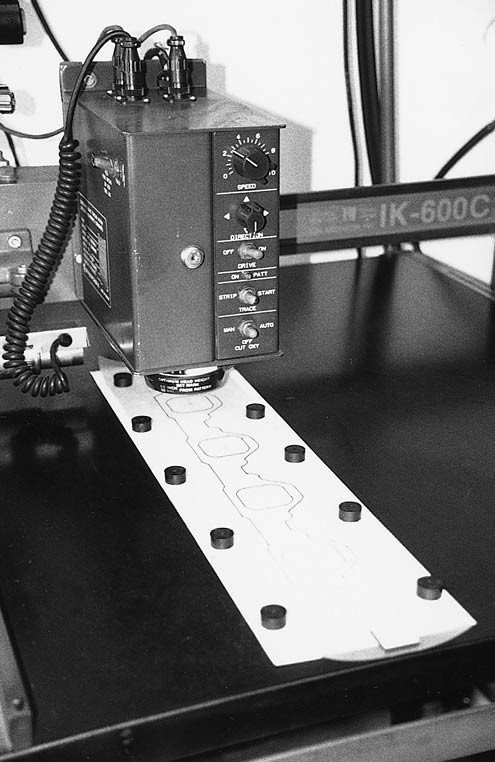

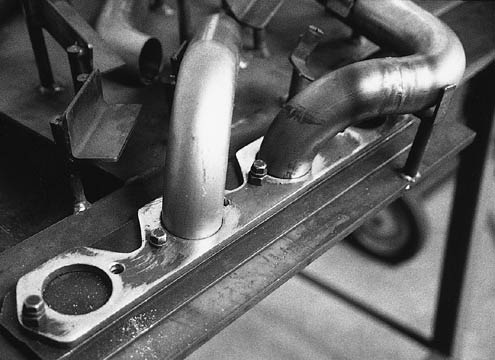

The first step in building a set of custom headers is building a thick one-piece flange for them. A tracer machine which is attached to a welder is used for precision cuts. The tracer follows the outline of this blueprint, while the welder cuts the flange from thick metal stock.

|

|

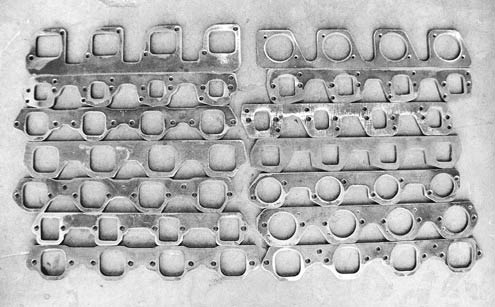

Here are the different flanges for common 302, 351W, 351C, and 460 applications.

Speacialty flanges for custom applications are available. |

|

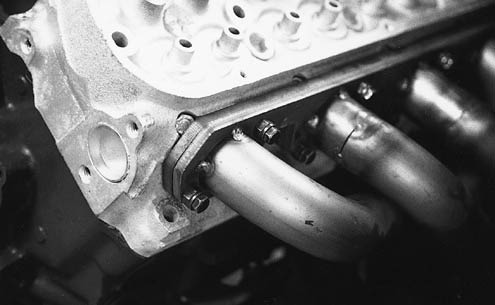

Some types of cylinder heads require port-plates in order to use larger primary tubes. These are included, if necessary, with our Big-Tube headers.

|

|

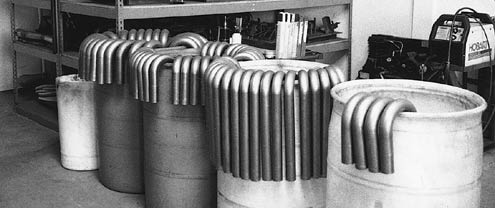

Tubing of every shape and diameter is available so that we can build headers that fit the available space under your ’Stang.

|

|

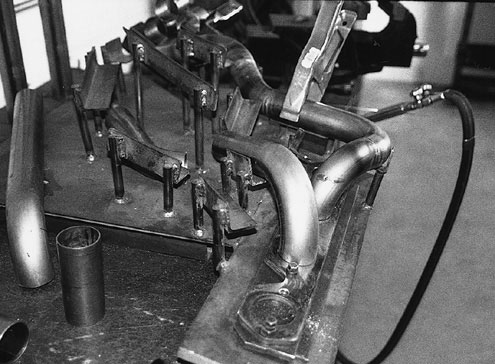

Once the flange has been constructed, it is placed in a custom-built jig which allows construction of the header tubes.

|

|

Here are the tubes actually in the process of being formed. Each tube is composed of as many as three or four different welded sections.

|

|

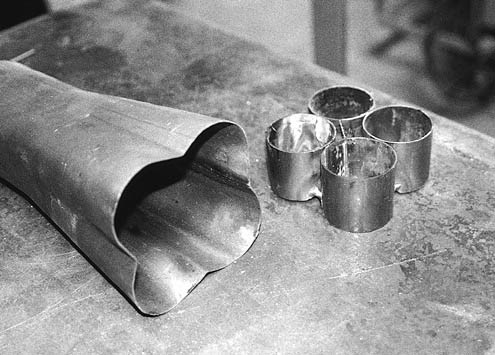

The collector begins life as these five pieces.

|

|

Four pipe sections, of a smaller diameter than the header primary, are welded together.

|

|

Here are the four tubes after welding.

Merge collectors are available for an additional cost. |

|

The four-into-one collector is then welded to the four smaller tubes. This is heli-arc'd for a stronger bond and smaller weld size.

|

|

The completed collector (in this case a 4-inch) is bolted to the header tubes. It can easily be removed, which makes installation a breeze. You can cut the tubes off the flange and install one tube at a time.

|

|

Here is our completed 2-inch race header. At a fraction of the cost of a custom header, you can't afford not to have a set!

|

|

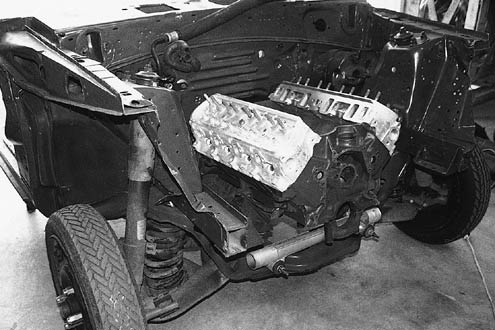

This is the cut-up 5.0 that was used to build and R&D new headers.

|

|

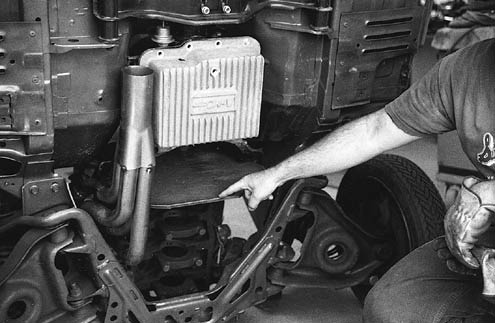

It's tricky fitting Big-Tube headers in a late model 'Stang. Pictured is massive 2" primary tubes on a 351W stuffed in a Fox Body.

Can you say free flowing exhaust, maximum horsepower? |

|

The cut-up car also saves the hassle of working on your back to fabricate the headers. You can see here the plate used to duplicate the JW bellhousing's dimensions.

|

|

The final inspection.

|